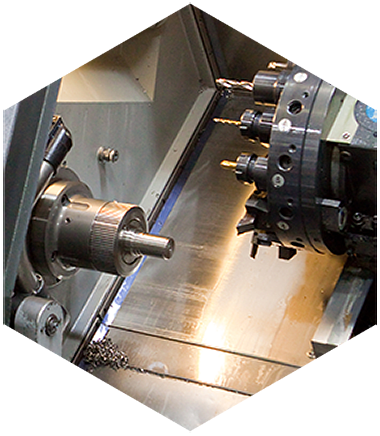

At Soltech we are proud of our fully modernised fleet of machinery, which allows us to complete every order to perfection. We have 10 CNC milling centres in both 3 and 5 axis formats, a number of them featuring robot loading stations. Then there are our 7 CNC lathes, all with automatic bar feed. The robot loading stations and automatic bar feeders allow production to be fully automated, with a consequent reduction in cost price. For shorter order runs we use our conventional lathes and milling machines.

The modern machines are controlled via a CAD/CAM system. This speeds programming, contributing a further cut in costs as well as reducing the risk of error.

Our Wenzel 3D measuring machine equips Soltech to measure complex products with extreme precision, during and following production. Measurement reports can be supplied along with the finished components if desired.

|

CNC Milling

|

Type

|

x-axis

|

y-axis

|

z-axis

|

Table dimensions

|

Steering

|

Axes

|

Load Robot

|

|

Victor

|

Vcenter 70

|

700

|

430

|

510

|

700 x 400

|

Fanuc 0i-MD

|

3

|

|

|

Victor

|

Vcenter 70

|

700

|

430

|

510

|

700 x 400

|

Fanuc 0i-MD

|

3

|

|

|

Victor

|

Vcenter 85

|

850

|

600

|

560

|

850 x 600

|

Fanuc 0i-MD

|

3

|

|

|

Victor

|

Vcenter A110

|

1.100

|

600

|

560

|

Ø 320 x 300

|

Fanuc 0i-MD

|

5

|

Yes

|

|

Victor

|

Vcenter A130

|

1.300

|

600

|

700

|

1.300 x 600

|

Fanuc 0i-MD

|

3

|

|

|

|

|

Accuway

|

UM 60

|

600

|

510

|

510

|

750 X 560

|

Fanuc 0i-MD

|

4

|

Yes

|

|

Accuway

|

UM 110

|

1.100

|

550

|

550

|

1.100 X 600

|

Fanuc 18i-M

|

4

|

Yes

|

|

|

|

Eagle

|

VMC 1300

|

1.300

|

635

|

635

|

1.300 x 600

|

Fanuc 0i-MD

|

3

|

|

|

|

Mazak

|

VTC 800/30 SR

|

3.000

|

800

|

720

|

3.500 X 820

|

Matrix

|

5

|

|

Mazak

|

Variaxis J600/5x

|

850

|

550

|

510

|

Ø 730 X 450

|

SmoothX

|

5

|

Yes

|

|

CNC Turning

|

Type

|

x-axis

|

Details

|

z-axis

|

Powered Tools

|

Steering

|

Transit

|

Barfeeder

|

Diam

|

Length

|

Load Robot

|

|

Muratec

|

MT 12

|

200

|

Double Turret

|

200

|

2 x 15

|

Fanuc

|

52

|

Yes

|

Ø 200

|

150

|

|

|

Mori-Seiki

|

SL 25

|

160

|

-

|

1.092

|

12

|

Fanuc MF-T6

|

52

|

Yes

|

Ø 240

|

500

|

|

|

Accuway

|

UT 200

|

220

|

-

|

600

|

10

|

Fanuc 0i-T

|

52

|

Yes

|

Ø 240

|

500

|

|

|

Victor

|

A26Y

|

260

|

Subspil 830

|

850

|

12

|

Fanuc 0i-TD

|

75

|

Yes

|

Ø 400

|

1.000

|

Yes

|

|

Gildemeister

|

Twin 42

|

220

|

Double Turret

|

380

|

2 x 12

|

Siemens SIN840d

|

42

|

Yes

|

Ø 100

|

320

|

|

|

CNC Swiss Turning

|

Type

|

X-axis

|

Details

|

Z-axis

|

Powered Tools

|

Steering

|

Transit

|

Barfeeder

|

Diam

|

Length

|

|

Manurhin

|

KMX 326

|

155

|

Subspindel

|

300

|

6 fixed x 6 powered

|

Fanuc

18i-T

|

26

|

Yes

|

Ø 26

|

1.500

|

|

Star

|

SV38R

|

|

Subspindel + steerded B-axis

|

|

2 x 10

|

Fanuc 31i-B5

|

38

|

Yes

|

Ø 38

|

350

|

|

Sawing

|

Type

|

Implementation

|

Auto Supply

|

Width

|

Lenght

|

|

Kasto

|

Twin A2

|

2 pillars system

|

Yes

|

260

|

260

|

|

Measurement

|

Type

|

x-axis

|

y-axis

|

z-axis

|

Software

|

|

Wenzel

|

LH65 3D CNC

|

650

|

750

|

450

|

Metrosoft QUARTIS®

|

|

Mitutoyo

|

PJ-A3000

|

630

|

630

|

80

|

QM-Data 200

|

|

Automation

|

Type

|

Maximum weight

|

Possibilities

|

|

BMO

|

PT50

|

50 kg

|

Product and pallethandling

|

|

Universal robots

|

UR10

|

10 kg

|

Mobile

|

De Vest 19 - 5555 XL Valkenswaard

De Vest 19 - 5555 XL Valkenswaard